Warehousing and logistics operations are under more pressure than ever before. Faster delivery expectations, labor shortages, tighter margins, and growing compliance requirements are forcing operators to rethink how their facilities are connected. As a result, warehouse connectivity is becoming a strategic priority.

At the same time, warehouses are becoming more digital, automated, and data driven. From handheld scanners and autonomous vehicles to real-time inventory systems and environmental monitoring, modern logistics depends on reliable, always-on connectivity.

This is why public cellular, private cellular networks, and IoT sensors are rapidly becoming critical infrastructure across warehousing and logistics, and why organizations are increasingly turning to solutions from Nextivity to make it all work seamlessly indoors.

Warehouses are notoriously difficult environments for wireless communications. They often have:

These challenges make consistent warehouse cellular connectivity difficult to achieve without dedicated planning and infrastructure.

Traditional Wi-Fi networks often struggle to provide reliable coverage at scale, particularly for mobile operations and high-density device environments. When connectivity drops, the consequences are immediate: lost productivity, scanning errors, delayed shipments, and frustrated staff.

This is driving a shift towards cellular-based connectivity models that are more resilient, secure, and scalable.

Public cellular networks (4G and 5G) remain fundamental to warehouse operations, particularly where staff, vehicles, and devices move between indoor and outdoor environments.

Key use cases include:

Reliable indoor public cellular coverage ensures that operations continue uninterrupted as people and assets move through loading docks, yards, and distribution centers. Without strong warehouse cellular connectivity, devices can lose signal just when speed and accuracy matter most.

Public cellular connecting people.

Private cellular networks, both private 4G and 5G, are becoming increasingly attractive for large warehouses, distribution hubs, and logistics campuses.

Why private cellular is gaining traction:

Private cellular gives operators greater control over their warehouse cellular connectivity, making it easier to support applications such as automated guided vehicles, real-time location systems, and machine-to-machine communications, which are areas where Wi-Fi can struggle to keep pace.

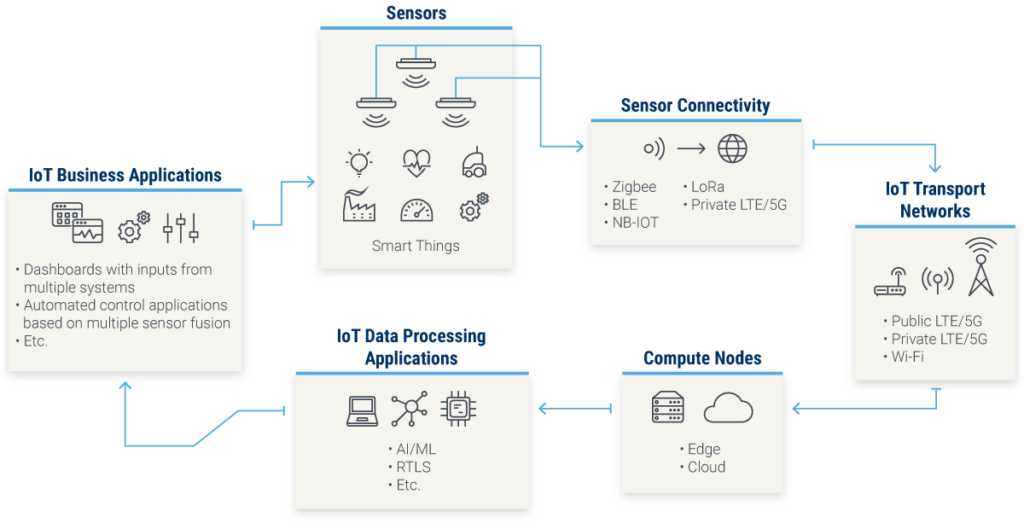

IoT sensors are transforming warehouses from static storage spaces into intelligent, responsive environments.

Common warehouse IoT applications include:

These sensors generate constant streams of data that must be transmitted reliably, often from hard-to-reach areas deep inside facilities. Scalable warehouse cellular connectivity enables thousands of sensors to operate reliably without constant reconfiguration or manual intervention.

IoT connecting insight to action.

Warehouse connectivity challenges are rarely solved by a single wireless technology. Public cellular, private cellular, and IoT each serve different operational needs, yet all rely on a common requirement: consistent, reliable indoor RF (radio frequency) coverage.

This is where a connectivity core becomes essential.

Rather than designing isolated networks for individual use cases, a connectivity core establishes a shared indoor wireless foundation that supports multiple services over time. Public cellular coverage can be deployed first to address workforce productivity and safety, while the same infrastructure can later support private cellular networks for automation and low-power IoT deployments for monitoring and insight.

Nextivity’s approach enables warehouses to design once and Do More With DAS, reducing complexity and avoiding repeated rip-and-replace projects as requirements evolve. By planning for multiple layers from the outset, operators gain flexibility, scalability, and long-term cost efficiency.

With a connectivity core in place, warehouses can:

Indoor connectivity core

With a connectivity core in place, the implications for the future of logistics are significant.

As warehousing and logistics continue to evolve, connectivity is no longer “nice to have.” It is a foundational capability that underpins safety, efficiency, automation, and long-term competitiveness.

Public cellular ensures people, devices, and vehicles remain connected as they move throughout the facility.

Private cellular provides the predictable performance and control required for automation and mission-critical operations.

IoT sensors deliver data that enables real-time monitoring, optimization, and smarter decision-making.

True value emerges when these capabilities are brought together on a shared connectivity foundation. By establishing a flexible, future-ready cellular core, warehouses can adapt to new applications and technologies without constantly rethinking their infrastructure.

This layered approach to warehouse connectivity allows operators to move at their own pace, addressing immediate operational challenges today while remaining ready for tomorrow’s demands.

In an industry defined by speed, resilience, and precision, a strong indoor connectivity foundation is quickly becoming a defining characteristic of modern, future-ready logistics operations.

As warehouses become larger, more automated, and more data-driven, connectivity must be treated as a strategic asset rather than a tactical fix. By establishing a strong indoor connectivity core, warehouse operators can address today’s operational challenges while building a flexible foundation for future innovation. In doing so, warehouses position themselves to adapt, scale, and compete in an increasingly connected logistics landscape.